Top Categories

Transform Your Space with Personalized Art Prints

Bring your walls to life with premium, customizable canvas prints. Whether it’s your favorite memories or inspiring art, Zebaco makes it easy to create beautiful, durable pieces that reflect your style.

High-Quality Prints

Affordable Custom Art

100% Satisfaction

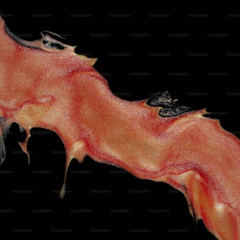

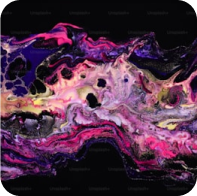

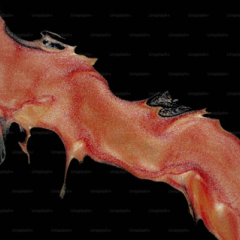

What’s On Sale

What Our Customers are Saying

Oliver Stone

"I recently purchased a stunning canvas from Zebaco, and I couldn't be happier with my choice! The vibrant colors and exquisite detail have truly transformed my living room. “

Amelia Rivers

"I recently purchased a stunning canvas from Zebaco, and I couldn't be happier with my choice! The vibrant colors and exquisite detail have truly transformed my living room. “

Ethan Hawke

"I recently purchased a stunning canvas from Zebaco, and I couldn't be happier with my choice! The vibrant colors and exquisite detail have truly transformed my living room. “

Sophia Bennett

"I recently purchased a stunning canvas from Zebaco, and I couldn't be happier with my choice! The vibrant colors and exquisite detail have truly transformed my living room. “

Sophia Bennett

"I recently purchased a stunning canvas from Zebaco, and I couldn't be happier with my choice! The vibrant colors and exquisite detail have truly transformed my living room. “

The Ultimate Guide to Custom Canvas Prints & Wall Art: Transforming Spaces with Premium Artistic Excellence

The realm of personalized canvas artwork has undergone tremendous transformation, evolving from simple printing processes to sophisticated artistic reproduction methods that rival traditional fine art creation. Custom canvas prints have emerged as the cornerstone of contemporary interior design, offering individuals and establishments the unprecedented ability to transform ordinary spaces into extraordinary visual experiences.

Modern canvas printing represents a convergence of artistic heritage and cutting-edge printing science. The process begins with understanding the fundamental properties of canvas materials, which range from traditional cotton weaves to revolutionary synthetic blends designed specifically for digital reproduction. Each substrate possesses unique characteristics that influence how pigments adhere, how colors develop over time, and how the final artwork responds to environmental conditions.

The journey from digital file to finished canvas artwork involves numerous critical stages, each requiring precise control and expert oversight. Initial color profiling ensures that digital images translate accurately to physical prints, while advanced printing machinery applies pigments with microscopic precision. The stretching process demands skilled craftsmanship, as improper tension can lead to warping, sagging, or premature deterioration of the artwork.

Contemporary canvas printing facilities employ sophisticated environmental controls to maintain optimal conditions throughout the production cycle. Humidity levels, temperature fluctuations, and air quality all play crucial roles in determining the final quality of custom canvas prints. Professional-grade facilities invest heavily in climate control systems that maintain consistent conditions, ensuring every piece meets exacting standards.

The Science Behind Premium Canvas Material Selection

Understanding canvas substrates requires deep knowledge of fiber properties, weave patterns, and surface treatments that influence print quality and longevity. Traditional cotton canvas remains popular due to its natural texture and proven durability, while synthetic alternatives offer enhanced color reproduction and resistance to environmental factors.

Polycanvas represents a significant advancement in canvas printing materials, combining the aesthetic appeal of natural fibers with the reliability of engineered materials. This substrate demonstrates exceptional dimensional stability, resisting expansion and contraction that can damage prints over time. The surface treatment applied to polycanvas enhances ink absorption while maintaining the tactile qualities that make canvas prints so appealing.

Standard canvas options utilize time-tested cotton weaves that have supported artistic creation for centuries. These materials offer natural texture variations that add depth and character to printed images. The organic nature of cotton fibers creates subtle irregularities that contribute to the handcrafted appearance many customers seek in their wall art.

Specialty substrates like Hahnemühle Monet Canvas represent the pinnacle of canvas printing materials. Originally developed for traditional painting techniques, these materials have been adapted for digital printing applications. The unique surface texture and superior color gamut capabilities make these substrates ideal for reproducing fine art pieces and photographic works requiring exceptional detail and color accuracy.

Metallic canvas substrates introduce an entirely different aesthetic dimension to custom prints. The incorporation of metallic particles within the canvas coating creates dynamic color shifts and luminous effects that change based on viewing angle and lighting conditions. These materials excel at reproducing images with strong contrast elements or metallic subjects, adding visual impact that traditional substrates cannot achieve.

Mastering the Twelve-Color Giclée Printing Process

The twelve-color Giclée printing system represents the current pinnacle of digital reproduction excellence, far surpassing traditional four-color printing processes in both color accuracy and tonal range. This sophisticated approach utilizes carefully formulated pigment sets that work in harmony to reproduce colors previously impossible to achieve through digital printing.

Pigment selection forms the foundation of superior Giclée printing. Unlike dye-based inks that can fade rapidly when exposed to light, pigment-based systems utilize microscopic particles suspended in carrier solutions. These particles resist photochemical breakdown, ensuring printed images maintain their original appearance for decades under normal display conditions.

The printing process itself requires precise calibration of multiple variables including droplet size, placement accuracy, and drying parameters. Advanced printheads deliver picolitre-sized droplets with positioning accuracy measured in micrometers. This precision enables smooth gradations, sharp detail reproduction, and consistent color throughout the entire print area.

Color management becomes increasingly complex with twelve-color systems, requiring sophisticated profiling techniques that account for substrate properties, environmental conditions, and viewing parameters. Professional operators create custom color profiles for each combination of substrate and printing conditions, ensuring consistent results across different production runs.

Exploring Frame Construction and Structural Integrity

The wooden frame supporting stretched canvas plays a crucial role in both the appearance and longevity of custom canvas prints. Modern frame construction utilizes carefully selected timber that has undergone extensive preparation to ensure dimensional stability and resistance to environmental changes.

European kiln-dried pine represents the gold standard for canvas frame construction. The kiln-drying process removes moisture content to precise levels, preventing subsequent shrinkage or expansion that could compromise canvas tension. Knotless varieties eliminate weak points that might fail under stress, while the natural resin content provides inherent resistance to insect damage and decay.

Frame milling requires precision machinery capable of producing consistent profiles across multiple components. The curved profile commonly used in contemporary frame construction serves multiple purposes beyond aesthetics. The rounded edges minimize contact area with the canvas back, reducing pressure points that could create impressions visible from the front. This design also facilitates air circulation, preventing moisture accumulation that could lead to mold or mildew formation.

Tensioning wedges represent a critical innovation in canvas frame design. These small wooden components allow for post-installation adjustments to canvas tension, compensating for natural relaxation that occurs over time. Proper wedge placement and adjustment require understanding of wood movement principles and canvas behavior under varying environmental conditions.

Finger joint construction provides superior strength compared to simpler joining methods. The interlocking profile distributes stress across a larger surface area, preventing separation under load. When combined with appropriate adhesives, finger joints create permanent bonds that maintain their integrity throughout the lifetime of the frame.

Canvas Depth Variations and Their Impact on Visual Presentation

The depth of canvas frames significantly influences the overall appearance and presence of wall art. Different depth options serve various aesthetic preferences and installation requirements, from subtle presentations that blend seamlessly with wall surfaces to bold displays that project dramatically into room spaces.

Shallow frames measuring 19mm in depth provide minimal projection from mounting surfaces, creating a contemporary flat presentation that works well in modern minimalist environments. These frames suit situations where artwork should integrate seamlessly with surrounding architecture rather than commanding attention through physical presence.

Medium depth frames at 38mm offer balanced presentation suitable for most residential and commercial applications. This depth provides sufficient projection to create visual interest while remaining proportionate to typical room scales. The moderate shadow cast by medium depth frames enhances the three-dimensional quality of the artwork without overwhelming adjacent elements.

Deep frames measuring 44mm create dramatic presentations that emphasize the physical presence of the artwork. These substantial frames cast pronounced shadows that change throughout the day as lighting conditions vary, adding dynamic visual interest. Deep frames work particularly well for large-scale pieces or in spaces with high ceilings where additional visual weight is beneficial.

The relationship between frame depth and image content requires careful consideration. Landscapes and architectural subjects often benefit from deeper frames that emphasize the spatial qualities of the depicted scenes. Portrait subjects may appear more intimate when presented in shallower frames that minimize physical barriers between viewer and subject.

Edge Finishing Techniques and Their Aesthetic Implications

Edge finishing represents one of the most critical decisions in custom canvas print production, dramatically influencing the final appearance and professionalism of the finished piece. Each finishing method creates distinct visual effects that complement different image types and design approaches.

Black edge finishing provides clean, professional presentation that works well with virtually any image content. The neutral black border creates a definitive boundary between artwork and surrounding space, ensuring viewer attention remains focused on the printed image. This approach particularly suits photographic images and artworks with complex color palettes where colored edges might create visual conflicts.

White edge finishing offers a lighter, more contemporary alternative that works exceptionally well with bright, colorful images. The white border provides gentle transition between artwork and wall surfaces, particularly effective in spaces with light-colored walls. This finishing method can make colors appear more vibrant by contrast while maintaining the clean, professional appearance expected in modern interiors.

Image wrap finishing extends the printed image around the canvas edges, creating seamless continuation of the artwork onto the frame sides. This approach works best with images containing appropriate content along the borders, such as landscapes with sky or water areas that can wrap naturally. Proper image wrap requires careful consideration of the original image composition to ensure critical elements remain visible on the front face.

Mirror wrap finishing creates sophisticated edge treatment by reflecting edge pixels across the frame sides. This method works particularly well with images containing gradual tonal transitions or solid colors along the borders. The mirrored effect creates subtle visual continuity while avoiding the potential issues associated with direct image wrapping of complex compositions.

Color Science and Pigment Durability in Custom Canvas Prints

Color science forms the foundation of modern custom canvas printing, ensuring that artwork maintains its vividness, clarity, and structural stability throughout decades of display. The interaction between pigments, substrates, and environmental factors influences not only the immediate aesthetic quality but also the long-term archival performance of prints. Whether the application involves fine art reproduction, photographic displays, or interior décor installations, understanding the chemical and physical principles behind pigment selection, substrate behavior, and environmental resistance is crucial. Advanced pigment technologies, precision-engineered canvases, and rigorous production protocols collectively determine whether a print resists fading, discoloration, and distortion over time.

Professional printmakers rely on research-driven approaches, testing methods, and color-management techniques that go far beyond conventional consumer printing systems. They evaluate how specific pigment formulations behave under varied conditions, including exposure to ultraviolet radiation, artificial lighting, airborne pollutants, and fluctuations in temperature and humidity. By combining scientific insight with sophisticated printing hardware, these practices deliver custom artworks with unparalleled chromatic fidelity, ensuring that even the most complex tonal transitions remain luminous and accurate long after installation.

Lightfastness as the Critical Benchmark for Pigment Stability

Lightfastness is widely regarded as the single most important characteristic for predicting the lifespan of printed images. It measures how effectively pigments resist fading or chromatic shift when subjected to prolonged illumination. Natural and artificial light both contain ultraviolet energy, which accelerates photochemical degradation of unstable colorants. Professional pigment sets undergo rigorous exposure tests using xenon arc lamps, fluorescent UV arrays, or high-intensity daylight simulators that replicate years of real-world display conditions within weeks. These evaluations produce ratings that indicate expected durability, allowing artists, photographers, and collectors to make informed choices about ink systems and display environments.

Inks with superior lightfastness ratings exhibit minimal loss of saturation or hue accuracy even after decades of exposure, especially when paired with museum-grade protective coatings. Prints displayed in direct sunlight without UV protection may suffer noticeable fading within a few years, whereas high-performance pigment inks combined with protective varnishes or glazing can retain near-original intensity for half a century or more. Strategic placement also plays a significant role: installing prints away from intense window light or high-temperature zones greatly reduces the risk of deterioration. The combination of well-selected pigments, stable substrates, and conscientious display practices creates prints that endure as heirlooms rather than disposable décor.

Expanded Color Gamut and High-Fidelity Reproduction

Color gamut refers to the full range of chromatic values that a printing system can reproduce. Traditional four-color CMYK processes, while economical, are inherently constrained, making it difficult to replicate extremely vivid tones, subtle gradations, or rare color combinations. Contemporary printing technologies now employ six-, eight-, or even twelve-color pigment arrays that fill these gaps, delivering an extended gamut with remarkable precision. Additional ink channels such as orange, green, red, or violet enhance smooth tonal transitions, accurate skin tones, and rich shadow details, ensuring that digital images translate seamlessly into physical artworks.

For photographers and visual artists, an expanded color gamut means more faithful reproduction of delicate pastels, deep blues, saturated crimsons, and complex neutral grays. Prints no longer exhibit compressed tonal zones or banding artifacts that plagued older printing systems. The inclusion of high-density black inks further refines contrast ratios, producing exceptional depth in monochrome images and subtle dimensionality in color compositions. This technological progress has transformed custom canvas printing into a platform capable of museum-quality results, with chromatic intensity that remains stable over time thanks to archival pigment chemistry.

Metamerism Control and Chromatic Consistency

Metamerism is the perceptual phenomenon in which two colors appear to match under one illumination source but diverge when the light changes. This discrepancy occurs because different pigments reflect varying spectral wavelengths even if they visually appear identical under a particular light. For artworks intended to hang in varied environments—residences with warm incandescent bulbs, offices with cool LED panels, or galleries with balanced daylight—metamerism can compromise visual consistency and artistic intent.

Professional printing operations combat metamerism through precise pigment formulation, rigorous spectral testing, and advanced color-profiling methods. ICC color profiles, device calibration routines, and uniform ink dispersion techniques ensure that printed colors maintain their intended relationships under diverse lighting conditions. By minimizing metameric shifts, prints retain harmony, balance, and coherence regardless of whether they are displayed in morning sunlight, evening lamplight, or commercial spot illumination. This attention to chromatic reliability preserves the emotional impact of the original design, delivering a consistent viewing experience to all audiences.

Substrate Engineering and Environmental Resistance

While pigments determine chromatic endurance, the substrate—the physical canvas—affects structural integrity, ink adhesion, and surface finish. High-quality cotton or poly-cotton canvases are manufactured to be dimensionally stable, pH-neutral, and resistant to environmental stress. Their surface coatings are formulated to optimize pigment absorption, prevent bleeding, and create a uniform matte or satin appearance. Archival substrates are designed to resist humidity-driven expansion and contraction, which can cause warping or cracking if left unchecked.

Pollutants such as ozone, sulfur dioxide, and airborne particulates can gradually discolor unprotected prints. Likewise, temperature swings and moisture exposure accelerate fiber degradation, particularly in low-grade materials. Using acid-free canvases paired with protective varnishes or laminates dramatically reduces these risks, creating an inert barrier that shields the image from atmospheric contaminants. Proper stretching and framing techniques further enhance substrate stability, ensuring that the physical print remains taut and free of distortion over many years.

Protective Coatings and Maintenance Strategies

Even when printed with the most resilient pigments and mounted on archival substrates, custom canvas prints benefit greatly from additional protective measures. Transparent UV-resistant varnishes or laminates serve as sacrificial layers that absorb damaging light energy before it reaches the ink layer. This approach can increase the longevity of vibrant colors and prevent surface abrasion caused by incidental contact. Glazing options such as museum-quality acrylic or low-reflection glass provide an additional safeguard while preserving visual clarity.

Routine maintenance also contributes to lasting image quality. Prints should be gently dusted with a soft microfiber cloth or natural-bristle brush to prevent particle accumulation without scratching the surface. Avoiding excessive moisture and chemical cleaners is essential, as these can compromise coatings or leave residues. Careful placement away from direct heat sources, such as radiators or halogen spotlights, further mitigates thermal stress. By combining these protective and maintenance practices with scientifically engineered pigment and substrate systems, custom canvas artworks maintain their original brilliance for generations.

Surface Texture and Its Influence on Artistic Expression

Canvas texture plays a fundamental role in how printed images are perceived and appreciated. The interplay between surface irregularities and applied pigments creates depth and visual interest that distinguishes canvas prints from smooth photographic papers or other printing substrates.

Natural canvas weaves create organic texture patterns that vary subtly across the surface. These variations interact with printed images in complex ways, sometimes enhancing certain elements while softening others. Understanding how specific image types respond to textured surfaces helps optimize the pairing of content with appropriate substrates.

Fine art reproduction benefits significantly from textured surfaces that simulate the appearance of original artistic media. Paintings, pastels, and other traditional artworks often appear more authentic when printed on substrates that approximate the original surface characteristics. The texture helps disguise the digital origin of the reproduction while enhancing the tactile qualities that make canvas prints appealing.

Photographic images require different considerations when printed on textured surfaces. While texture can add artistic interpretation to photographs, it may also interfere with fine detail reproduction. The key lies in matching texture scale to image content, ensuring that surface variations enhance rather than detract from the intended visual impact.

Professional Mounting and Display Considerations

Proper mounting represents a critical aspect of custom canvas print presentation that extends far beyond simple wall attachment. Professional mounting systems account for canvas expansion and contraction, wall characteristics, and viewing optimization to ensure artwork maintains its intended appearance throughout its display lifetime.

Wall preparation plays a crucial role in successful canvas mounting. Different wall materials require specific fastening approaches, from drywall anchors to masonry fixings. Understanding load distribution helps prevent damage to both artwork and mounting surfaces while ensuring secure attachment that withstands normal environmental stresses.

Hanging height affects viewer engagement and room proportion relationships. Professional interior designers typically position artwork with center points at eye level, though this guideline requires adjustment based on ceiling height, furniture placement, and intended viewing distances. Large custom canvas prints may warrant different positioning strategies that account for their substantial visual presence.

Lighting considerations significantly impact how custom canvas prints are perceived and appreciated. Natural lighting provides ideal conditions for viewing canvas artwork, though artificial lighting systems can enhance presentation when properly designed. Understanding how different light sources interact with canvas textures and pigments helps optimize display conditions.

Environmental Factors Affecting Canvas Print Longevity

The longevity of custom canvas prints depends not only on pigment durability and substrate quality but also on the environmental conditions in which they are produced, displayed, and maintained. Atmospheric fluctuations, airborne contaminants, and inconsistent climate control can progressively undermine structural stability, leading to discoloration, distortion, and surface degradation over time. A comprehensive understanding of these factors empowers both creators and collectors to make informed decisions regarding print production specifications, framing techniques, and display placement. By integrating scientific knowledge with proper handling practices, custom canvas artworks can preserve their vividness, dimensional integrity, and archival value for decades rather than years.

Humidity Fluctuations and Dimensional Stability

Humidity is one of the most critical environmental variables influencing the long-term stability of canvas materials. Natural fibers such as cotton and linen are hygroscopic, meaning they readily absorb and release moisture depending on ambient conditions. When relative humidity rises, canvas fibers swell, causing the material to expand and lose tautness. When humidity drops, those same fibers contract, potentially leading to excessive tension, surface rippling, or even cracking of the printed layer. Repeated expansion and contraction cycles accelerate mechanical stress within both the substrate and the ink film, weakening the overall structure of the artwork.

Professional mounting systems often mitigate these dimensional changes by employing flexible stretching and attachment methods that allow the canvas to shift slightly without damaging the image. Acid-free liners, moisture-resistant coatings, and protective varnishes further stabilize the surface, reducing water vapor penetration. Climate-controlled environments, ideally maintaining a consistent relative humidity around 40% to 55%, provide the most effective solution for preserving print integrity. In homes, offices, and galleries where such precise control is impractical, selecting robust canvas composites and applying archival protective layers can significantly extend print longevity.

Temperature Variations and Accelerated Aging

Temperature instability represents another major environmental challenge for canvas print preservation. High heat accelerates chemical reactions that degrade both organic and synthetic materials, causing pigments to fade more rapidly and substrates to weaken. Elevated temperatures also intensify off-gassing from framing components and varnishes, leading to discoloration or unwanted deposits on the artwork surface. Conversely, low temperatures may cause stiffening of the ink layer, making it more vulnerable to cracking under mechanical stress.

Rapid temperature swings create expansion and contraction cycles similar to those caused by humidity fluctuations. These movements may produce micro-fractures, warping, or detachment of the ink film from its base. Displaying custom canvas prints in climate-controlled interiors—avoiding direct proximity to heating ducts, radiators, or poorly insulated exterior walls—ensures a stable thermal environment. Consistent moderate temperatures between 18°C and 24°C provide an ideal range for maintaining pigment vibrancy and structural resilience over decades of display.

Airborne Contaminants and Material Interaction

Air quality plays a decisive role in determining how well printed artworks resist degradation. Pollutants such as ozone, sulfur dioxide, and nitrogen oxides can react with pigments or protective coatings, causing chemical alterations that appear as yellowing, hazing, or uneven color shifts. Dust particles settle on unprotected surfaces, embedding microscopic abrasives that dull the image over time. Industrial regions and dense urban settings often have elevated contaminant levels that exacerbate these effects.

Preventive measures include selecting canvas substrates with sealed coatings that resist pollutant absorption and using protective varnishes that act as sacrificial layers. Regular surface cleaning with soft brushes or microfiber cloths removes accumulated particulates before they can cause long-term abrasion. Frames equipped with airtight backing boards reduce airflow and shield the artwork from corrosive atmospheric agents. These strategies collectively ensure that the printed image maintains clarity, saturation, and surface uniformity even in less-than-ideal environmental conditions.

Ultraviolet Radiation and Photochemical Degradation

Ultraviolet radiation, whether from direct sunlight or strong artificial lighting, is one of the most destructive environmental factors affecting custom canvas prints. UV photons carry enough energy to break chemical bonds in both pigments and substrate materials, resulting in gradual fading, loss of contrast, and a brittle surface texture. Prints displayed near windows or under high-intensity spotlights without UV protection may lose perceptible vibrancy within a few years.

Modern archival varnishes and glazing materials incorporate UV inhibitors that absorb or reflect damaging wavelengths before they penetrate the print surface. Museum-quality acrylics and specialized glass offer high optical clarity while blocking more than 95% of harmful radiation. Proper display positioning—away from direct beams of sunlight—further reduces photochemical stress. When combined with high-lightfastness pigment inks, these protective measures dramatically extend the aesthetic lifespan of canvas artworks.

Mechanical Stress and Structural Deformation

Beyond chemical and photochemical influences, physical stress can also compromise the longevity of custom prints. Canvas mounted under excessive tension may stretch unevenly, while prints displayed in areas prone to vibration or impact may suffer frame distortion or surface creasing. Over-tightening during stretching or framing can cause edge tearing or premature loosening as the material reacts to environmental changes.

Employing gallery-wrap methods with adjustable corner keys allows periodic retensioning without damaging the image. Floating frames with spacer systems help prevent direct pressure on the canvas edges while maintaining an elegant presentation. Careful handling during installation and transport minimizes accidental abrasions, punctures, or compressive damage. When prints are displayed in high-traffic commercial environments, protective glazing or laminated overlays reduce the risk of surface contact while preserving visual fidelity.

Maintenance Protocols and Preventive Conservation

Even the most durable pigment systems and substrates require active maintenance to achieve their full archival potential. Routine cleaning with dry, non-abrasive tools prevents dust accumulation without introducing moisture or chemical residues. Protective coatings should be inspected periodically for signs of degradation, as these layers are often the first to show environmental wear. If varnish becomes clouded or compromised, professional restoration services can reapply protective treatments without harming the underlying image.

Owners of high-value custom prints may benefit from consulting conservation specialists to evaluate framing materials, mounting methods, and display conditions. The use of archival-grade backings, UV-blocking enclosures, and controlled illumination levels represents a proactive approach to safeguarding printed artworks. By combining scientific knowledge with practical upkeep, prints retain their original chromatic brilliance and surface integrity over generations.

Integrating Environmental Control with Artistic Vision

Understanding the relationship between environmental conditions and print durability empowers both creators and collectors to protect the visual and cultural value of custom canvas artworks. The science behind humidity control, temperature regulation, air quality management, and UV shielding informs better material choices, framing designs, and display strategies. These efforts ensure that vibrant colors, fine details, and subtle tonal gradations remain intact long after production.

By integrating rigorous production standards with informed conservation practices, canvas prints evolve from temporary decorative items into lasting artistic investments. Environmental awareness allows artworks to thrive in diverse settings—from residential interiors to public exhibitions—without succumbing to premature aging or degradation. As printing technology and protective materials continue to advance, the synergy between scientific precision and artistic expression promises a future where custom prints retain their brilliance, dimensional stability, and cultural significance for decades, if not centuries.

Quality Control Standards in Professional Canvas Production

Professional canvas printing operations maintain rigorous quality control standards throughout every stage of production, from initial file preparation through final packaging and shipping. These standards ensure consistent results that meet customer expectations while maintaining the reputation of the printing facility.

File inspection represents the first quality checkpoint in professional canvas production. Experienced technicians evaluate digital files for resolution adequacy, color profile accuracy, and potential printing issues before production begins. This preliminary review prevents problems that could compromise final print quality while providing opportunities to communicate with customers about potential improvements.

Print evaluation involves multiple checkpoints during the actual printing process. Advanced printing systems incorporate real-time monitoring that detects inconsistencies in ink delivery, substrate feeding, or print head performance. Operators trained in color evaluation examine prints during production to ensure colors remain consistent throughout the printing process.

Finishing inspection ensures that stretching, framing, and edge finishing meet established standards before artwork leaves the production facility. This final quality checkpoint identifies any issues with frame construction, canvas tension, or edge treatment that could affect customer satisfaction or product longevity.

Market Trends in Custom Canvas Wall Art Preferences

Contemporary preferences in custom canvas wall art reflect broader cultural shifts toward personalization, sustainability, and authentic expression. Understanding these trends helps both creators and sellers anticipate customer demands and position their offerings effectively in competitive markets.

Personalization trends continue driving demand for custom canvas prints that reflect individual tastes, experiences, and aesthetic preferences. Customers increasingly seek artwork that tells personal stories or captures meaningful moments, moving beyond generic decorative pieces toward truly customized visual expressions.

Size preferences have evolved toward larger formats that create statement pieces within residential and commercial spaces. Modern room scales and open floor plans accommodate substantial artworks that would have overwhelmed traditional room configurations. This trend toward larger pieces influences both production capabilities and pricing strategies.

Color palette preferences shift periodically in response to broader design movements and cultural influences. Current trends favor both dramatic contrasts and subtle tonal variations, depending on specific market segments and regional preferences. Understanding these preferences helps guide both image selection and production optimization.

Substrate Performance Under Various Display Conditions

Different canvas substrates demonstrate varying performance characteristics when subjected to the environmental conditions typically encountered in residential and commercial display situations. Understanding these performance differences enables informed substrate selection that optimizes both appearance and longevity.

Cotton-based substrates excel in stable indoor environments where temperature and humidity remain relatively constant. The natural fiber structure provides excellent ink absorption and color development while maintaining the traditional canvas appearance valued by many customers. However, cotton materials may prove more sensitive to environmental fluctuations compared to synthetic alternatives.

Synthetic substrates offer enhanced stability under challenging environmental conditions, including areas with significant temperature or humidity variations. These materials resist dimensional changes that can affect canvas tension while providing consistent surface characteristics that ensure uniform ink absorption across the entire print area.

Specialty substrates designed for specific applications demonstrate optimized performance for particular image types or display requirements. Fine art substrates prioritize color accuracy and archival stability, while photographic substrates emphasize detail reproduction and smooth tonal transitions.

Frame Construction Methods and Structural Considerations

Professional frame construction employs time-tested joinery methods combined with modern materials science to create structural foundations capable of supporting canvas prints throughout their expected lifespan. Understanding these construction principles helps both producers and consumers appreciate the engineering that underlies quality canvas products.

Mortise and tenon joints provide exceptional strength and longevity in frame construction, though they require skilled craftsmanship and specialized equipment. These traditional joints distribute stress across substantial surface areas while maintaining tight fits that resist loosening over time.

Finger joint construction offers excellent strength characteristics while enabling efficient production methods suitable for custom canvas print manufacturing. The interlocking profile creates mechanical bonds that resist separation under load while providing adequate surface area for adhesive applications.

Corner reinforcement methods vary based on frame size and intended load requirements. Small frames may require only properly executed joints and adhesives, while larger pieces benefit from additional mechanical fasteners or reinforcement plates that distribute stress across multiple points.

Wood selection criteria encompass multiple factors including species characteristics, moisture content, grain orientation, and defect frequency. Different wood species demonstrate varying properties regarding strength, stability, and workability, influencing both production efficiency and final product quality.

Color Matching and Profile Management Systems

Accurate color reproduction in custom canvas prints requires sophisticated color management systems that account for the complex interactions between digital files, printing equipment, substrates, and viewing conditions. Professional operations invest heavily in calibration equipment and procedures that ensure consistent color reproduction across different production runs and environmental conditions.

Monitor calibration forms the foundation of effective color management, ensuring that digital images appear accurately on display devices used for file preparation and evaluation. Professional-grade monitors undergo regular calibration using colorimeters that measure actual light output and compare it to established standards.

Printer profiling involves creating custom color profiles that describe how specific combinations of printing equipment and substrates reproduce colors. These profiles account for the unique characteristics of each substrate and printing configuration, enabling accurate color prediction and reproduction.

Proofing systems provide final verification that printed colors match customer expectations before full production begins. Hard proofing creates actual prints using production equipment and materials, while soft proofing utilizes calibrated monitors to simulate expected print appearance.

Understanding Image Resolution Requirements for Various Print Sizes

Image resolution requirements for custom canvas prints depend on multiple factors including intended viewing distance, image content characteristics, and quality expectations. Professional understanding of resolution principles enables optimization of file preparation procedures that balance file size management with quality requirements.

Pixel density calculations determine minimum file sizes required for specific print dimensions. While traditional guidelines suggest 300 pixels per inch for photographic prints, canvas prints may accommodate lower pixel densities due to viewing distance considerations and surface texture characteristics that help disguise pixelation.

Upsampling procedures can enhance undersized digital files through interpolation algorithms that add pixel information based on surrounding data. Modern upsampling software utilizes artificial intelligence to predict likely pixel values, creating enlarged files that maintain visual quality despite increased dimensions.

Image sharpening becomes particularly important when preparing files for canvas printing. The texture of canvas surfaces can soften image details, requiring compensatory sharpening that restores apparent detail without creating artifacts. Professional sharpening procedures account for substrate characteristics and printing processes to optimize final appearance.

Surface Treatment Innovations in Modern Canvas Manufacturing

Contemporary canvas manufacturing incorporates sophisticated surface treatments that enhance both print quality and long-term performance. These treatments represent significant advancement over traditional canvas preparations, addressing specific challenges associated with digital printing applications.

Ink receptive coatings optimize pigment absorption while maintaining surface characteristics that contribute to the canvas aesthetic. These specialized treatments ensure uniform ink penetration across the entire surface while preventing excessive absorption that could dull colors or create inconsistent coverage.

Moisture barrier treatments protect canvas materials from environmental humidity while maintaining breathability necessary for dimensional stability. These treatments utilize micro-porous technologies that allow air movement while blocking liquid moisture that could cause staining or dimensional changes.

UV protective treatments incorporated into canvas surfaces provide additional safeguards against light-induced fading and degradation. These treatments work in conjunction with pigment lightfastness characteristics to extend the display life of custom canvas prints under normal indoor lighting conditions.

Print on Demand Logistics and Fulfillment Strategies

Modern print on demand operations require sophisticated logistics systems that coordinate file management, production scheduling, quality control, and shipping procedures to deliver custom canvas prints efficiently and reliably. Understanding these systems helps both sellers and customers appreciate the complexity involved in custom print fulfillment.

Order processing begins with automated file handling systems that receive, process, and prepare digital images for production. These systems perform preliminary quality checks, apply necessary color corrections, and generate production files optimized for specific printing equipment and substrates.

Production scheduling algorithms balance order priority, substrate availability, equipment capacity, and shipping deadlines to optimize facility efficiency while meeting customer delivery expectations. Advanced systems account for seasonal variations, holiday periods, and special event deadlines that may require expedited processing.

Quality assurance procedures integrated throughout the fulfillment process ensure that defective products are identified and corrected before shipping. These procedures include automated inspection systems that detect print defects, as well as manual evaluation stages that assess overall quality and finishing standards.

Packaging and Shipping Considerations for Canvas Protection

Protecting custom canvas prints during shipping requires specialized packaging approaches that account for the unique vulnerabilities of stretched canvas products. Professional shipping systems utilize custom packaging solutions designed specifically for canvas prints of various sizes and configurations.

Corner protection represents a critical element in canvas shipping systems. Canvas corners are particularly vulnerable to impact damage during handling and transportation. Professional packaging incorporates rigid corner protectors that distribute impact forces while maintaining package dimensions that facilitate efficient shipping.

Surface protection prevents scratching, moisture damage, and contamination during transit. Protective films or tissues applied to canvas surfaces must be carefully selected to avoid adhesive residues or texture imprinting that could affect final appearance. Breathable materials prevent moisture accumulation while providing adequate protection against physical damage.

Package design considerations include weight distribution, handling requirements, and carrier compatibility. Oversized canvas prints may require special handling procedures or carrier services, influencing both packaging design and shipping costs. Efficient package design minimizes dimensional weight while providing adequate protection.

Customer Service Excellence in Custom Print Operations

Delivering exceptional customer service in custom canvas print operations requires understanding the unique challenges and expectations associated with personalized artwork production. Customers invest both financial resources and emotional significance in custom prints, creating service expectations that extend beyond simple product delivery.

Pre-production consultation helps customers understand available options, resolution requirements, and design considerations that affect final results. Knowledgeable service representatives can guide customers through substrate selection, sizing decisions, and finishing options that optimize their specific requirements.

Production communication keeps customers informed about order status, potential delays, and quality considerations that may arise during manufacturing. Proactive communication demonstrates professionalism while providing opportunities to address concerns before they become problems.

Post-delivery support addresses installation questions, care instructions, and any quality concerns that may emerge after customers receive their custom canvas prints. Comprehensive support policies that include replacement guarantees and satisfaction assurances build customer confidence and encourage repeat business.

Artistic Reproduction Ethics and Copyright Considerations

The ability to reproduce any image as custom canvas prints raises important ethical and legal considerations regarding intellectual property rights, artistic attribution, and commercial use permissions. Professional printing operations must navigate these considerations while providing customers with guidance that ensures lawful and ethical use of printing services.

Copyright law applies to virtually all photographic and artistic works, regardless of their source or availability online. Customers must possess appropriate rights or permissions before requesting reproduction of copyrighted materials as custom canvas prints. Understanding fair use principles and obtaining proper licensing represents essential aspects of responsible custom printing practices.

Artist attribution becomes important when reproducing fine art pieces or commissioned works. Even when reproduction rights are available, proper attribution may be required by contract or professional ethics. Clear policies regarding attribution requirements help both customers and printing operations avoid potential legal complications.

Commercial use restrictions may apply to certain types of images or artistic works, even when personal use reproduction is permitted. Customers planning to use custom canvas prints for business purposes must understand and comply with licensing requirements that may differ significantly from personal use permissions.

Interior Design Integration Strategies for Canvas Wall Art

Successfully integrating custom canvas prints into interior design schemes requires understanding spatial relationships, color theory, and lighting principles that influence how artwork interacts with surrounding architectural and decorative elements.

Scale relationships between artwork and room dimensions significantly impact visual balance and aesthetic success. Large canvas prints can anchor room designs and create focal points, while smaller pieces may serve accent roles that complement other decorative elements. Understanding these relationships enables optimal sizing decisions that enhance rather than overwhelm interior spaces.

Color coordination involves more than simple color matching between artwork and room elements. Professional designers consider undertones, saturation levels, and color temperature relationships that create harmonious palettes while maintaining visual interest. Custom canvas prints offer opportunities to introduce specific colors that tie together diverse room elements.

Placement strategies account for viewing angles, lighting conditions, and traffic patterns within spaces. Optimal placement ensures artwork receives appropriate attention while avoiding locations where environmental conditions might compromise longevity or viewing quality.

Production Workflow Optimization in Professional Facilities

Efficient production workflows in custom canvas printing facilities require careful coordination of multiple processes, from initial order receipt through final quality inspection and packaging. Understanding these workflows helps both facility operators and customers appreciate the complexity involved in delivering consistently excellent results.

File preparation procedures establish standardized approaches to image processing, color correction, and print file generation. Automated systems handle routine processing tasks while providing checkpoints for manual intervention when specialized attention is required. These procedures ensure consistent file quality while minimizing processing time and potential errors.

Production scheduling systems balance multiple competing priorities including order urgency, substrate availability, equipment capacity, and quality requirements. Advanced scheduling algorithms optimize resource utilization while maintaining flexibility necessary to accommodate rush orders and unexpected production challenges.

Quality checkpoints integrated throughout production workflows identify potential issues early in the process, minimizing waste and ensuring customer satisfaction. These checkpoints include automated inspection systems and manual evaluation procedures performed by trained quality technicians.

Specialty Printing Techniques for Enhanced Visual Impact

Beyond standard canvas printing methods, specialty techniques offer enhanced visual effects and unique aesthetic characteristics that distinguish premium custom prints from conventional offerings. These techniques require specialized equipment and expertise but provide opportunities for truly exceptional artistic expression.

Texture enhancement techniques apply additional surface treatments that modify canvas characteristics after printing. These treatments can create raised surface elements, subtle texture variations, or enhanced tactile qualities that add dimensional interest to finished prints. Careful application ensures that enhancements complement rather than overwhelm the printed image.

Varnish applications provide both protective and aesthetic benefits, creating surface characteristics that simulate traditional painting media. Different varnish formulations produce effects ranging from matte surfaces that eliminate reflections to high-gloss finishes that intensify colors and create dramatic light interactions.

Mixed media incorporation allows combination of printed elements with traditional artistic media, creating unique pieces that blend digital and analog creation methods. These approaches require careful planning to ensure compatibility between different materials and techniques while maintaining long-term stability.

Canvas Print Care and Maintenance Procedures

Proper care and maintenance significantly extend the lifespan and appearance quality of custom canvas prints. Understanding appropriate cleaning methods, environmental considerations, and preventive measures helps customers protect their investments while maintaining optimal appearance.

Cleaning procedures for canvas prints require gentle approaches that remove dust and surface contaminants without damaging the printed surface or canvas texture. Soft brushes and low-suction vacuum systems provide effective cleaning while minimizing mechanical stress on canvas fibers and printed pigments.

Environmental monitoring helps identify conditions that may threaten canvas print integrity. Simple tools for measuring humidity and temperature enable customers to maintain optimal display conditions while identifying situations that may require environmental modification or artwork relocation.

Preventive maintenance includes periodic inspection for signs of canvas relaxation, frame movement, or environmental damage. Early identification of potential issues enables corrective action before problems become serious enough to require professional restoration or replacement.

Commercial Applications for Custom Canvas Print Products

Custom canvas prints serve diverse commercial applications beyond residential decoration, creating opportunities for specialized market segments with unique requirements and quality expectations. Understanding these applications helps both producers and sellers identify potential market opportunities.

Corporate environments utilize custom canvas prints for branding, employee recognition, and atmospheric enhancement. Large-scale prints displaying company imagery, mission statements, or achievement celebrations create visual impact while reinforcing organizational identity. Professional quality becomes particularly important in these applications where artwork reflects company image and values.

Hospitality applications require canvas prints that withstand intensive use while maintaining attractive appearance. Hotels, restaurants, and other hospitality venues benefit from custom artwork that creates distinctive atmospheres while enduring frequent exposure to diverse environmental conditions and handling requirements.

Healthcare facilities increasingly incorporate custom canvas prints as elements of healing environments that support patient wellbeing and staff morale. These applications require careful attention to subject matter, color psychology, and maintenance requirements specific to medical environments.

International Shipping and Customs Considerations

Shipping custom canvas prints internationally requires understanding customs regulations, duty calculations, and documentation requirements that vary significantly between countries and regions. Professional fulfillment operations maintain expertise in international shipping requirements to ensure smooth delivery while minimizing unexpected costs or delays.

Customs classification systems categorize printed artwork according to material composition, production methods, and intended use. Proper classification ensures accurate duty calculations while avoiding delays associated with incorrect documentation. Understanding these systems helps both shippers and recipients prepare for international transactions.

Documentation requirements vary substantially between countries, with some requiring detailed descriptions of artwork content, production methods, and material specifications. Comprehensive documentation reduces the likelihood of customs delays while ensuring compliance with import regulations.

Value declarations must accurately reflect the commercial value of custom canvas prints while considering local regulations regarding gift shipments, personal effects, and commercial merchandise. Accurate declarations prevent complications while ensuring appropriate insurance coverage during transit.

Emerging Technologies in Canvas Print Production

The canvas printing industry continues evolving through adoption of emerging technologies that enhance quality, efficiency, and creative possibilities. Understanding these developments helps both industry participants and customers appreciate ongoing improvements in custom canvas print capabilities.

Advanced print head technologies enable higher resolution output with improved color accuracy and reduced production time. New print head designs incorporate more nozzles operating at higher frequencies, enabling faster printing without compromising quality standards.

Artificial intelligence applications in color management systems provide automated optimization of print parameters based on image content analysis. These systems can identify image characteristics and automatically adjust printing parameters to optimize color reproduction and detail clarity.

Automated finishing systems reduce manual labor requirements while improving consistency in stretching and framing operations. Robotic systems can precisely control canvas tension and ensure uniform edge finishing across multiple production units.

Sustainable Practices in Canvas Print Manufacturing

Environmental responsibility has become increasingly important in canvas print manufacturing, driving adoption of sustainable materials, processes, and business practices that minimize environmental impact while maintaining quality standards.

Eco-friendly substrate options utilize recycled content, sustainable forestry practices, or alternative fiber sources that reduce environmental impact compared to traditional materials. These substrates maintain quality characteristics required for custom canvas prints while supporting environmental responsibility goals.

Water-based pigment systems reduce volatile organic compound emissions compared to solvent-based alternatives. These systems provide excellent color reproduction and durability while creating safer working environments and reducing environmental impact from production operations.

Waste reduction initiatives minimize material consumption through optimized cutting patterns, substrate recycling programs, and efficient inventory management. These practices reduce both environmental impact and production costs while maintaining quality standards.

Digital Asset Management for Custom Print Operations

Effective digital asset management represents a critical operational requirement for custom canvas print facilities handling hundreds or thousands of unique image files daily. Professional systems ensure file integrity, enable efficient retrieval, and maintain customer privacy while supporting high-volume production requirements.

File organization systems utilize standardized naming conventions, folder structures, and metadata tags that enable rapid file location and retrieval. These systems must accommodate diverse file formats, multiple resolution versions, and customer-specific requirements while maintaining organization that supports efficient workflow management.

Backup procedures protect both customer files and production data against loss due to equipment failure, cyber attacks, or human error. Professional backup systems maintain multiple copies of critical data in geographically separated locations while ensuring rapid recovery capabilities when needed.

Security measures protect customer intellectual property and personal information throughout the production process. These measures include access controls, encryption protocols, and audit trails that ensure customer data remains confidential while enabling authorized personnel to complete production tasks.

Print Resolution Optimization for Different Viewing Distances

Optimizing print resolution for custom canvas prints requires understanding the relationship between pixel density, viewing distance, and perceived image quality. Different applications and display contexts require different resolution approaches that balance file size management with quality requirements.

Near viewing applications such as small prints displayed in intimate spaces require higher pixel densities to maintain quality under close inspection. These situations demand careful attention to detail reproduction and edge sharpness that becomes apparent when viewers examine prints from short distances.

Distance viewing scenarios allow lower pixel densities without compromising perceived quality, enabling efficient file management and faster production times. Large prints intended for viewing from several feet away can utilize resolution optimization that maintains visual impact while reducing file processing requirements.

Content-specific considerations influence resolution requirements based on image characteristics. Highly detailed images with fine patterns or text elements require higher resolutions than images with smooth gradations or simple compositions that remain effective at lower pixel densities.

Color Temperature and Lighting Interaction Effects

The interaction between lighting conditions and custom canvas prints significantly influences color perception and overall visual impact. Understanding these relationships enables both optimal display conditions and appropriate color adjustments during production that account for expected viewing environments.

Natural lighting provides ideal conditions for viewing canvas prints, offering full spectrum illumination that reveals true colors and subtle tonal variations. However, natural lighting varies throughout the day and across seasons, requiring consideration of these changes when planning display locations and color optimization.

Artificial lighting systems create consistent illumination but may emphasize certain color ranges while suppressing others. Different lamp types demonstrate varying color rendering capabilities that influence how canvas prints appear under their illumination. Understanding these characteristics enables appropriate lighting selection for optimal artwork presentation.

Color temperature relationships between lighting and artwork affect perceived warmth or coolness of displayed images. Warm lighting emphasizes red and yellow color ranges while suppressing blues and violets, while cool lighting produces opposite effects. Professional display planning accounts for these relationships to optimize color perception.

Custom Frame Profile Design and Manufacturing

Frame profiles significantly influence the aesthetic character and structural performance of custom canvas prints. Understanding profile design principles enables selection of frame configurations that optimize both appearance and longevity for specific applications and aesthetic preferences.

Curved profile designs minimize contact area between frame edges and canvas backing, reducing pressure points that could create visible impressions. The curve radius and transition geometry require careful engineering to provide adequate support while minimizing surface contact.

Rabbet depth and geometry determine how canvas edges integrate with frame structures. Proper rabbet design ensures secure canvas retention while providing adequate depth for tensioning adjustments and future re-stretching operations that may become necessary over time.

Surface finishing applied to frame profiles affects both appearance and durability. Different finishing options provide varying levels of protection against moisture, wear, and environmental factors while contributing to overall aesthetic character of finished canvas prints.

Regional Variations in Canvas Print Preferences and Standards

Global markets for custom canvas prints demonstrate significant regional variations in aesthetic preferences, quality expectations, and purchasing behaviors. Understanding these differences enables effective market positioning and product optimization for specific geographic regions.

European markets traditionally emphasize fine art reproduction quality and archival longevity, reflecting cultural appreciation for artistic heritage and long-term value. These markets often accept higher pricing for premium materials and production methods that ensure exceptional quality and durability.

North American preferences tend toward larger formats and bold visual impact, reflecting architectural scales and design preferences that favor statement pieces. Fast delivery expectations and competitive pricing pressures influence production and fulfillment strategies in these markets.

Asian markets demonstrate growing sophistication in quality expectations while maintaining sensitivity to pricing considerations. Rapid market development and changing consumer preferences require flexible production capabilities that can adapt to evolving requirements.

Quality Assessment Methodologies for Canvas Print Evaluation

Professional evaluation of custom canvas print quality requires systematic assessment methodologies that examine multiple quality aspects objectively. These methodologies provide consistent quality standards while identifying improvement opportunities in production processes.

Color accuracy assessment utilizes colorimetric measurement equipment that quantifies color differences between original images and printed reproductions. These measurements provide objective data that supplements visual evaluation while enabling statistical process control approaches to quality management.

Detail reproduction evaluation examines how effectively printing processes capture fine image elements such as texture details, sharp edges, and subtle tonal transitions. Standardized test images enable consistent evaluation across different production runs and equipment configurations.

Surface quality inspection identifies printing artifacts, substrate defects, or finishing inconsistencies that could affect customer satisfaction. Trained inspectors utilize standardized lighting conditions and evaluation procedures that ensure consistent quality assessment.

Frame Assembly Procedures and Quality Control

Professional frame assembly for custom canvas prints requires skilled craftsmanship combined with systematic quality control procedures that ensure structural integrity and aesthetic consistency across all production units.

Component preparation involves precision cutting, surface preparation, and pre-assembly inspection that identifies potential quality issues before final assembly begins. These procedures prevent quality problems while optimizing assembly efficiency and minimizing waste.

Assembly sequences follow standardized procedures that ensure consistent joint quality, proper alignment, and adequate curing time for adhesive bonds. Experienced assemblers understand how environmental conditions affect assembly procedures and adjust techniques accordingly.

Final Thoughts

Custom canvas prints and wall art embody far more than decorative accents; they represent a union of aesthetic vision, advanced printing technology, and scientific precision that elevates ordinary interiors into curated environments. In an age where personalization defines modern living, these artworks provide a tangible expression of individual taste, cultural appreciation, and design sensibility. Whether installed in private residences, corporate offices, or public spaces, high-quality canvas prints deliver enduring beauty, emotional resonance, and long-term value.

Investing in premium-grade materials and pigment technologies ensures that each piece retains its vibrancy and structural stability for decades rather than years. Advanced printing systems with expanded color gamuts capture intricate tonalities, subtle gradients, and rich shadow depth, achieving fidelity that rivals traditional fine art. When paired with archival substrates and protective coatings, these artworks become resilient against the environmental factors that often compromise lesser-quality prints. Controlled humidity, stable temperatures, and UV protection play pivotal roles in safeguarding each canvas, but proper placement, framing, and periodic maintenance are equally vital to preserving their original brilliance.

The transformative power of wall art lies not only in its visual impact but in its ability to shape the atmosphere of a room. Thoughtfully chosen prints introduce color harmony, texture, and thematic balance, influencing mood and creating immersive experiences. Whether an interior calls for bold contemporary statements, subtle abstract compositions, or timeless photographic reproductions, custom printing empowers creators and collectors to align art precisely with architectural character and personal identity. This seamless integration turns blank walls into narratives, reflecting both artistry and intention.

Moreover, technological innovation has democratized access to exceptional quality. What was once reserved for museum-level collections is now available to discerning homeowners, designers, and businesses who seek to make meaningful impressions. Precision color profiling, lightfast pigments, and carefully engineered substrates ensure that today’s canvas prints are not ephemeral décor but lasting investments in visual culture. Each work embodies a fusion of artistry and craftsmanship, where modern science protects creative expression from the passage of time.

Ultimately, the true value of custom canvas prints lies in their ability to endure—both as physical objects and as carriers of meaning. By understanding the interplay of pigments, substrates, and environmental conditions, collectors and creators gain control over how artworks age, ensuring that colors remain vibrant, edges stay crisp, and textures hold their integrity. Whether displayed under gallery spotlights or in the soft glow of a living room, premium prints reward thoughtful stewardship with decades of unchanging beauty.

As the art of printing continues to evolve, the boundaries between digital design and tangible craftsmanship are dissolving, paving the way for works that are not only visually stunning but archivally sound. The ultimate guide to custom canvas prints and wall art affirms that excellence comes from more than visual appeal—it emerges from a dedication to material quality, scientific rigor, and aesthetic refinement. In merging innovation with timeless artistry, these prints transform spaces, inspire connection, and preserve beauty for generations to come.